Product Overview

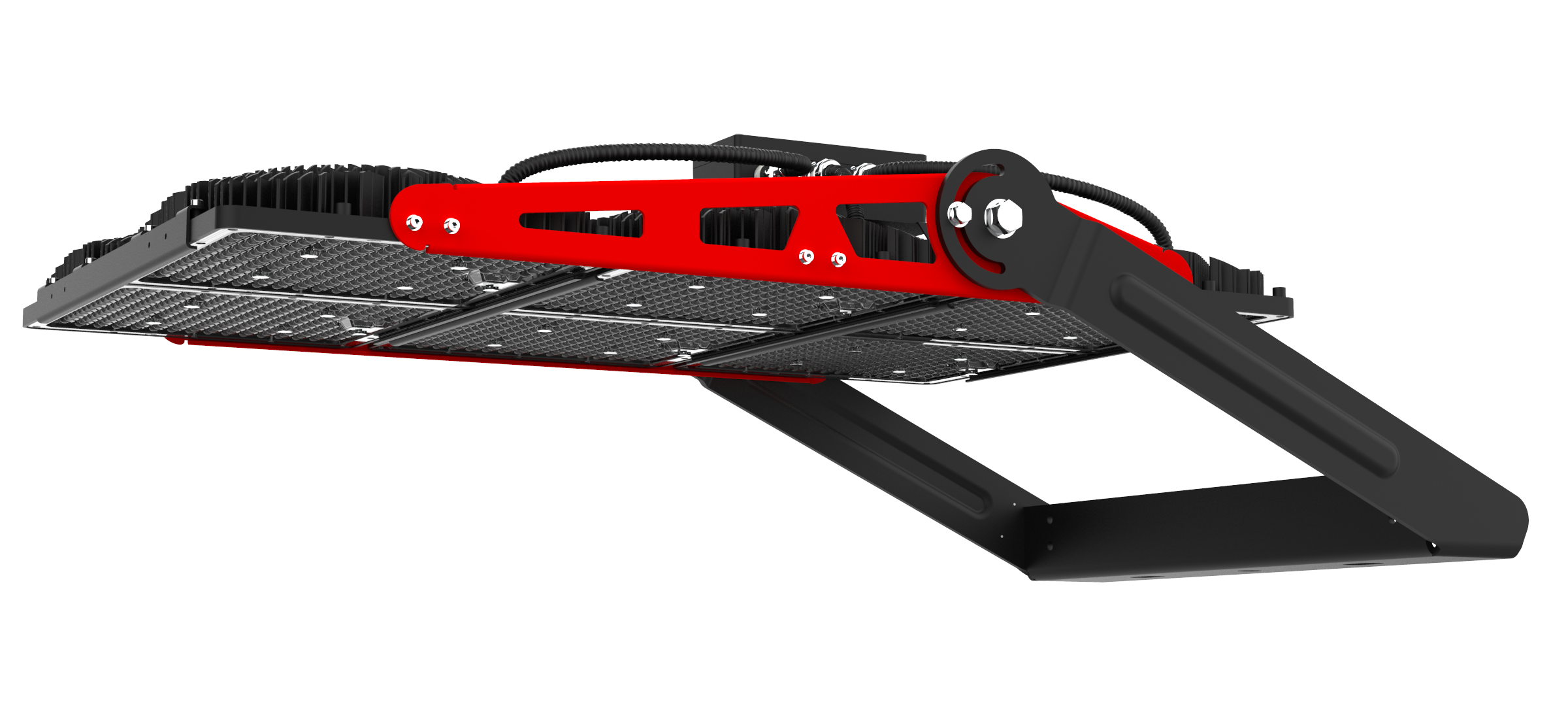

Challenger 1 LED

The Challenger 1 LED range represents the cutting edge of LED floodlighting. With unrivalled performance and the most low profile design on the market, the Challenger 1 LED is perfect for a large number of applications across many industries.

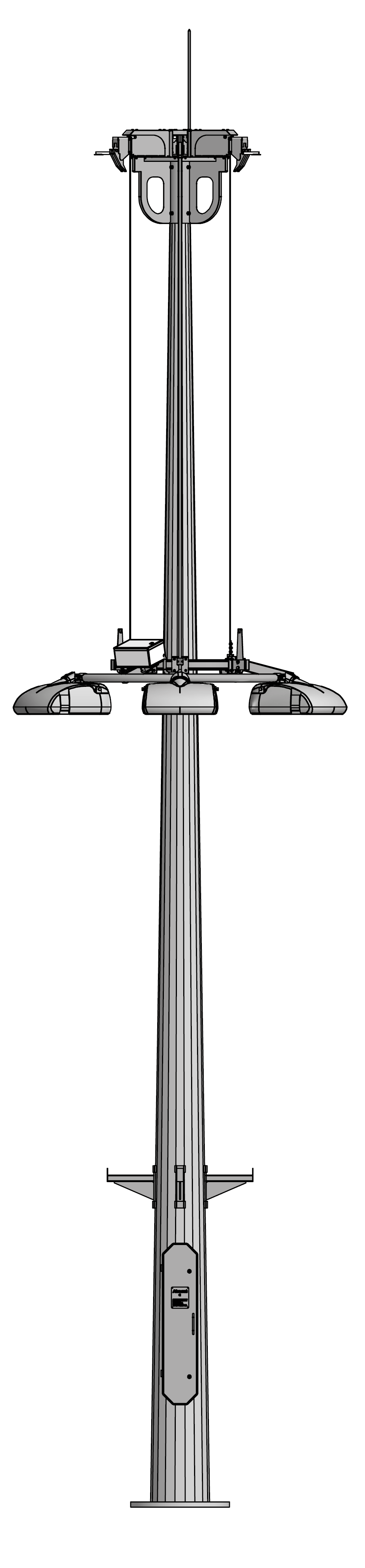

Product Overview

Raising and Lowering Winch Masts

The range of lowering headframe masts from Abacus deliver precision engineering solutions for a great variety of different projects – from major container port terminals to international airports