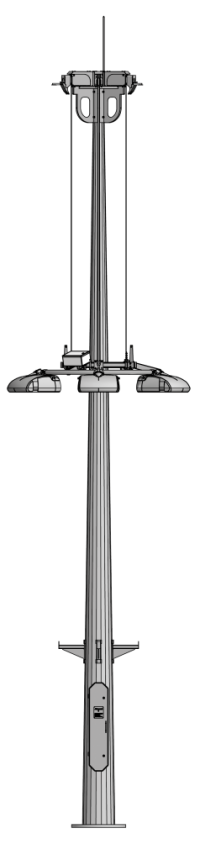

The range of lowering headframe masts from Abacus deliver precision engineering solutions for a great variety of different projects – from major container port terminals to international airports.

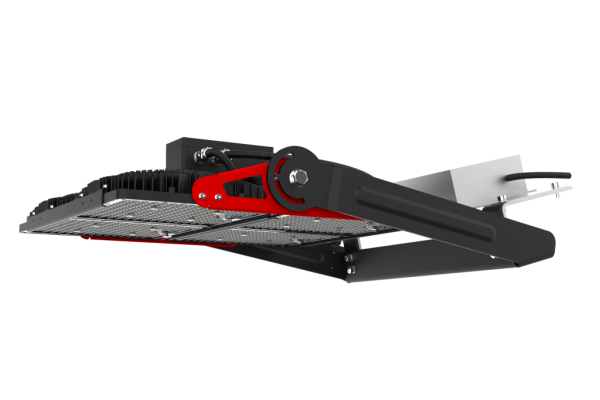

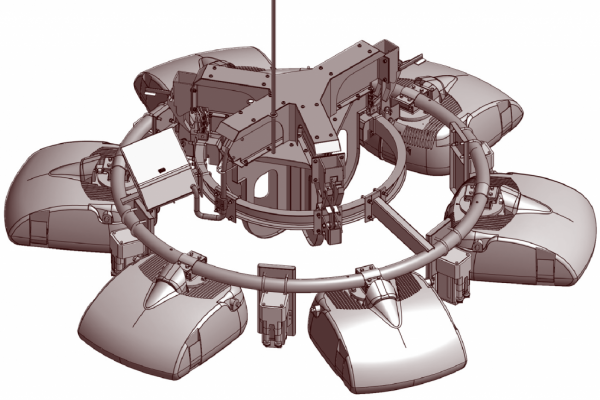

The engineered headframe, with its secure three-pulley system, is available with or without our innovative latching system. A single multi-core electric cable has its own independent pulley, meaning it doesn’t become entangled with other cables in the mast.

Features

- Headframe supported by three stainless steel cables for longer-term stability than twin cable systems

- Option to install mechanical latching system on three arms, to release strain on cables when headframe is in the operating position

- Headframe supplied prepared ready for installation, complete with three cables looped for dropping into the mast shaft and junction box for the multicore cable mounted on headframe

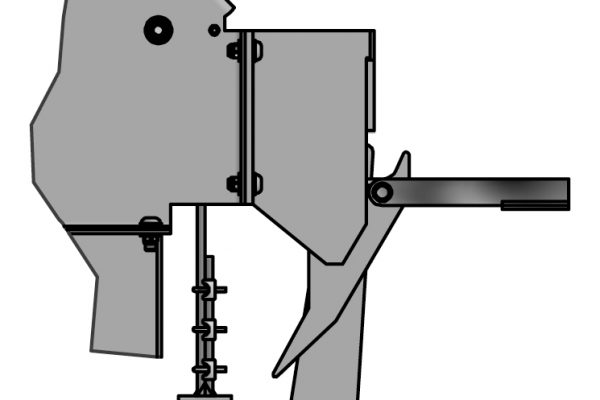

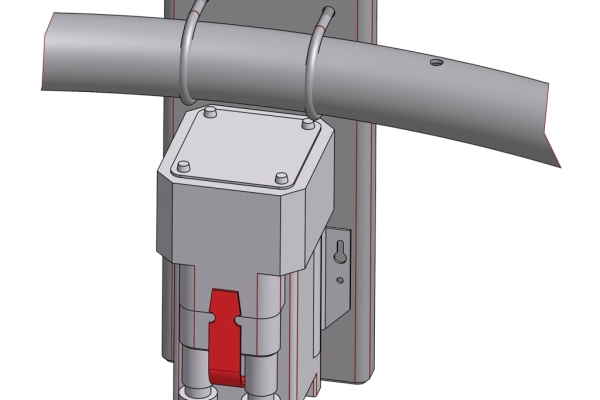

- Single 275kg or single 550kg winch located in the base of the mast. The winch is self-sustaining, with a gravity latch on the input shaft

- A 10mm earth terminal is provided in the base of the mast

- Single multicore cable for all lanterns is located on an independent pulley, stopping multiple cables from becoming entangled inside the mast

- Single multicore – with 18 cores on the 275kg winch mast (for up

to 8 floodlights/lanterns), or 25 cores on the 550kg model (for up to

12 lanterns) - A multicore electric cable, with integral signal cables for CCTV and WiFi, is available on request

- Electrical cable is supplied with a plug and socket at lower end. This means you can detach the cable and power the headframe at ground level using a separate extension cable

- A lightweight dual-speed reversible power tool is supplied with its own mounting bracket, which is clamped directly to the body of the mast. A remote hand-held box with non-latching buttons controls the unit, enabling the operator to stand at a safe distance when lowering

Build your mast

Step 1

Identify the correct Abacus floodlight from the lighting design and then…

Step 2

Select the correct headframe option based on:

- The floodlight arrangement

- External IP65 control gear

Step 3

Select the central assembly code determined by:

- Mast height e.g. 30m is RLW-HF-30M-xxx-xx

- Multicore electric cable, for 275kg winch is 18core (18C) & 550kg winch is 25core (25C); e.g. RLW-HF-30M-18C-XX

- Whether the latching system is required (-L) or not (-NL); e.g. RLW-HF-30M-18C-NL

Note: the central assembly is delivered to site fully assembled with stainless steel cables and multicore cable factory-assembled ready for

immediate installation.

Step 4

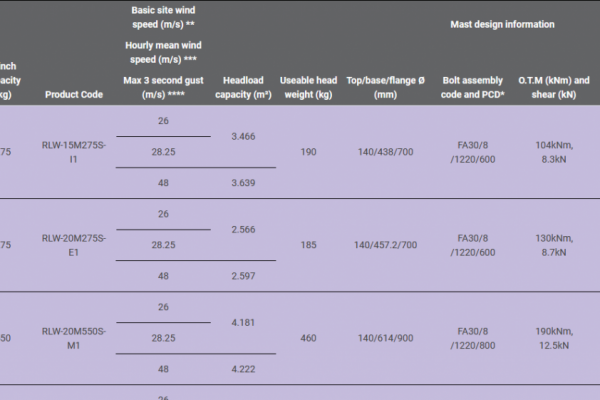

Select the correct mast structure based on:

- Mast height

- Winch capacity (determined by headframe choice)

- Site wind speed and headframe area

For each height and winch capacity there is a light duty and medium duty mast option, which covers most requirements. Other mast structures for higher wind loads are available on request.

Step 5

Select any necessary accessories for example:

- The floodlight mounting bracket, required if a floodlight with stirrup is selected

- Power tool operating system, dependent on winch capacity

- Lightning rod